-

Glued laminated timber (glulam), also known as engineered lumber, is constructed by bonding individual pieces of wood together. Each piece has serrated ends to facilitate interlocking, allowing for the desired length to be achieved. Additionally, the grain direction of all laminations is parallel to the length of the glulam beam. This structural design enables smaller diameter trees harvested from forests to be utilized in creating large beams. Therefore, the selection of wood is not dependent on mature trees, yet still allows for architectural designs with large spans and high strength.

Douglas fir, one of the strongest commercial tree species, is commonly used in the production of glued laminated timber. Glulam beams made from Douglas fir are stiffer and harder than natural wood of the same size, and even possess greater toughness than steel of the same weight. This allows for the design of longer beams without the need for excessive support. As a result, architects have more flexibility in their designs, making glued laminated timber suitable for various applications such as residential buildings, commercial structures, sports arenas, and highway bridges.

Adventage of bestwood

-

For different outdoor applications, Douglas fir can be treated with various chemical preservatives such as water-based ACQ, MCQ, or oil-based Hi Clear preservatives, or coal tar, to provide long-term durability under harsh natural weather conditions. It is commonly used in large-span wooden bridges, highway sound barriers and guardrails, bay docks, and railway sleepers.

Engineered Lumber - Douglas Fir Glulam Beams

Due to its superior strength-to-weight ratio compared to steel, Douglas fir is commonly selected as the material for engineered glulam beams. Graded Douglas fir boards are bonded and fixed with weather-resistant phenol formaldehyde (PF) glue to customize various dimensional requirements. Compared to solid wood of the same specifications, glulam beams have higher structural strength, providing architects and designers with more diverse design options. In architectural planning, the application of glulam beams will differ from conventional RC steel structures, as glulam beams not only provide basic structural load-bearing strength but also showcase the natural appearance of wood without the need for additional decoration.

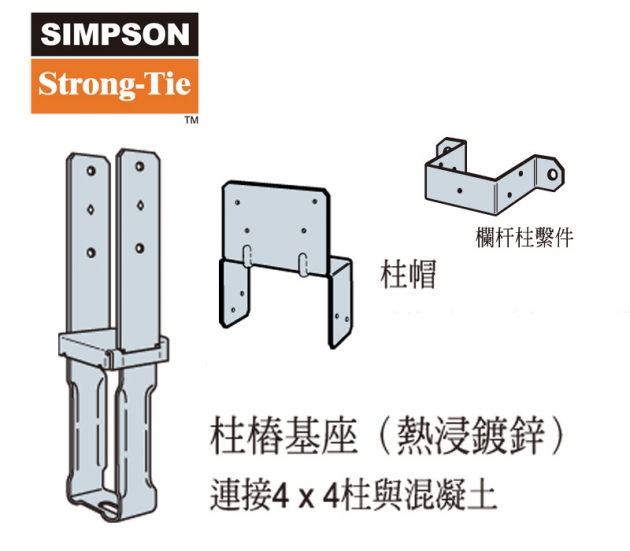

Glulam Beam Connectors and Fasteners

Correct connection and fixation methods are crucial for ensuring the structural integrity of buildings, especially for glulam beams. Improper fixation can lead to serious consequences. Design engineers must fully consider the position and quantity of metal connectors to meet the load requirements of the structure. If the glulam beams have a one-hour fire resistance requirement, steel support connectors and fasteners should also be protected to achieve the same fire resistance rating. -

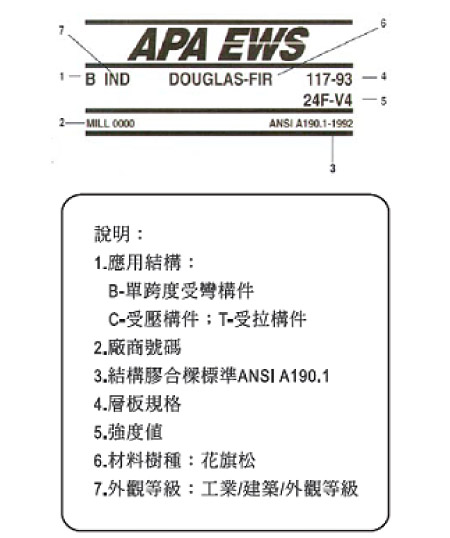

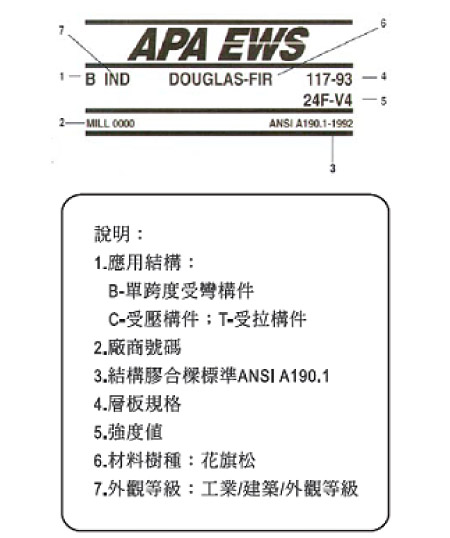

If glulam beams are manufactured by members of the American Plywood Association, they bear the trademark "APA EWS" on their products. This trademark not only represents stringent quality control and testing by the producer but also signifies compliance with the American National Standard for Structural Glued Laminated Timber ANSI A190.1-92.

ANSI A190.1-92

The required product conditions specified by the standard are listed on the APA EWS trademark, such as "24F-V4", where "24F" indicates a stress surface bending strength of 2400 psi, and "V" represents visual grading; the final number indicates the internal wood composition of the glulam beam. The APA EWS trademark is recognized by all major building codes listed in National Evaluation Service Report NER-QA397. This report is specifically developed for glulam beams manufactured by members of the American Plywood Association.

-

Glued Laminated Timber Specificaions

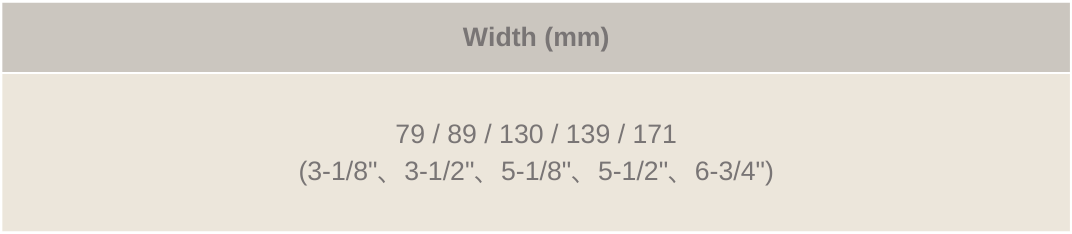

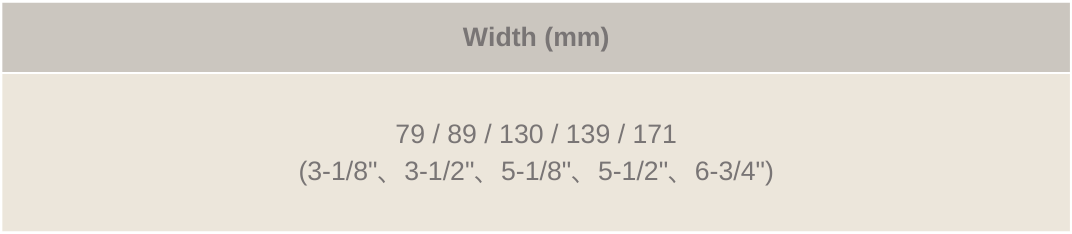

Glulam beams are available in standard sizes and custom sizes. Prefabricated glulam beams are manufactured according to standard sizes and then cut to the required length when ordered. Typically, standard widths include 79mm, 89mm, 130mm, 139mm, and 171mm (3-1/8", 3-1/2", 5-1/8", 5-1/2", and 6-3/4"), which can meet the needs of most residential construction applications.

When architects have special design and styling requirements, such as long spans, heavy loads, or other designs, custom glulam beams can be used. Custom glulam beams can be made in almost any size and shape to meet various design conditions. Common custom glulam beams include curved beams, pitched beams, and radial arches.

-

Glued Laminated Timber Characteristic

Glued laminated timber (glulam), also known as engineered lumber, is constructed by bonding individual pieces of wood together. Each piece has serrated ends to facilitate interlocking, allowing for the desired length to be achieved. Additionally, the grain direction of all laminations is parallel to the length of the glulam beam. This structural design enables smaller diameter trees harvested from forests to be utilized in creating large beams. Therefore, the selection of wood is not dependent on mature trees, yet still allows for architectural designs with large spans and high strength.

Douglas fir, one of the strongest commercial tree species, is commonly used in the production of glued laminated timber. Glulam beams made from Douglas fir are stiffer and harder than natural wood of the same size, and even possess greater toughness than steel of the same weight. This allows for the design of longer beams without the need for excessive support. As a result, architects have more flexibility in their designs, making glued laminated timber suitable for various applications such as residential buildings, commercial structures, sports arenas, and highway bridges.

Adventage of bestwood

-

Glued Laminated Timber Applications

For different outdoor applications, Douglas fir can be treated with various chemical preservatives such as water-based ACQ, MCQ, or oil-based Hi Clear preservatives, or coal tar, to provide long-term durability under harsh natural weather conditions. It is commonly used in large-span wooden bridges, highway sound barriers and guardrails, bay docks, and railway sleepers.

Engineered Lumber - Douglas Fir Glulam Beams

Due to its superior strength-to-weight ratio compared to steel, Douglas fir is commonly selected as the material for engineered glulam beams. Graded Douglas fir boards are bonded and fixed with weather-resistant phenol formaldehyde (PF) glue to customize various dimensional requirements. Compared to solid wood of the same specifications, glulam beams have higher structural strength, providing architects and designers with more diverse design options. In architectural planning, the application of glulam beams will differ from conventional RC steel structures, as glulam beams not only provide basic structural load-bearing strength but also showcase the natural appearance of wood without the need for additional decoration.

Glulam Beam Connectors and Fasteners

Correct connection and fixation methods are crucial for ensuring the structural integrity of buildings, especially for glulam beams. Improper fixation can lead to serious consequences. Design engineers must fully consider the position and quantity of metal connectors to meet the load requirements of the structure. If the glulam beams have a one-hour fire resistance requirement, steel support connectors and fasteners should also be protected to achieve the same fire resistance rating. -

Glued Laminated Timber Specification

If glulam beams are manufactured by members of the American Plywood Association, they bear the trademark "APA EWS" on their products. This trademark not only represents stringent quality control and testing by the producer but also signifies compliance with the American National Standard for Structural Glued Laminated Timber ANSI A190.1-92.

ANSI A190.1-92

The required product conditions specified by the standard are listed on the APA EWS trademark, such as "24F-V4", where "24F" indicates a stress surface bending strength of 2400 psi, and "V" represents visual grading; the final number indicates the internal wood composition of the glulam beam. The APA EWS trademark is recognized by all major building codes listed in National Evaluation Service Report NER-QA397. This report is specifically developed for glulam beams manufactured by members of the American Plywood Association.

-

Glued Laminated Timber Specificaions

Glued Laminated Timber Specificaions

Glulam beams are available in standard sizes and custom sizes. Prefabricated glulam beams are manufactured according to standard sizes and then cut to the required length when ordered. Typically, standard widths include 79mm, 89mm, 130mm, 139mm, and 171mm (3-1/8", 3-1/2", 5-1/8", 5-1/2", and 6-3/4"), which can meet the needs of most residential construction applications.

When architects have special design and styling requirements, such as long spans, heavy loads, or other designs, custom glulam beams can be used. Custom glulam beams can be made in almost any size and shape to meet various design conditions. Common custom glulam beams include curved beams, pitched beams, and radial arches.