Length x Width

• 1220 X 2440 mm

Thickness

• 9/11/15/18mm

European Standard EN 300 Classification

• OSB1 / OSB2/ OSB3

*bestwood offers OSB2/ OSB3 grades

Also known as Oriented Strand Board (OSB), it is a special type of engineered wood panel product with wide-ranging applications.

OSB, or oriented strand board, can be used both indoors and outdoors, commonly employed in wood structures, packaging materials, interior decoration materials, furniture tabletops, etc.

-

OSB (Oriented Strand Board), unlike typical plywood and solid wood boards found in the market, is a special engineered wood panel product made by bonding layers of rectangular wood strands together from corner to corner.

The material used in OSB production isn't scrap wood from other processing activities but rather utilizes the entire log efficiently.

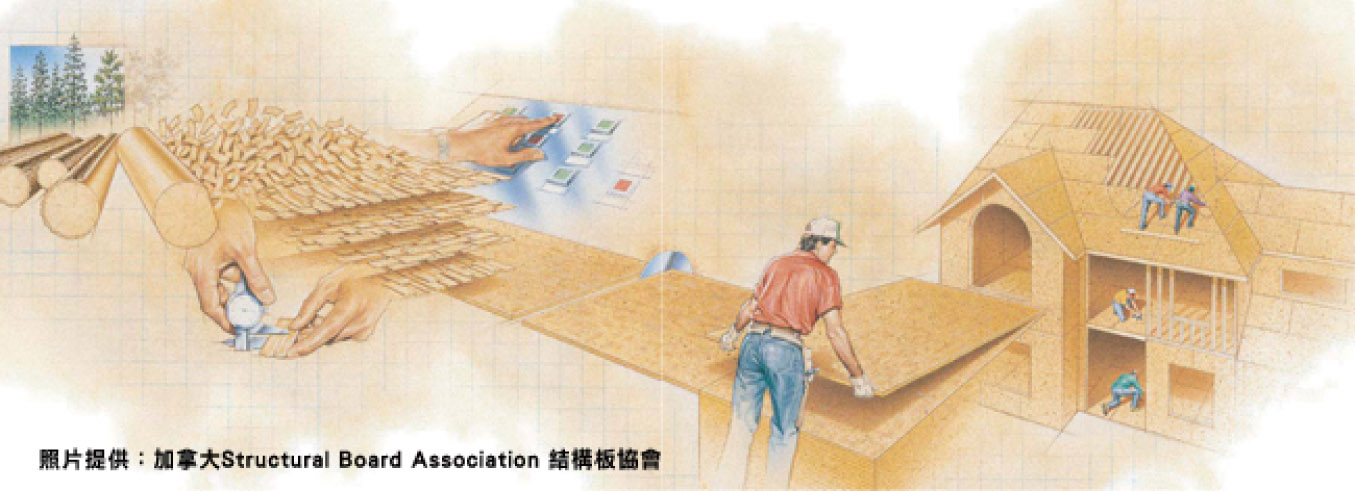

Manufacturing Process of OSB

During production, raw materials are sawn to specified dimensions, debarked, and processed into thin wood strands, typically averaging 4 inches long and 1 inch wide. After drying, these wood strands are mixed with adhesive resin and wax, then laid out in layers in alternating directions—vertically and horizontally—to enhance the density of the board and form a unique texture. Finally, the assembled layers undergo high-temperature continuous hot pressing to produce continuous panels of various thicknesses, which are then cut to the desired dimensions for construction and transportation.

Commonly used dimensions for OSB are 4 feet x 8 feet (1220mm x 2440mm).

Environmentally Friendly Wood Board

OSB emits very low levels of formaldehyde, typically as low as 0.012ppm. In fact, this emission level is lower than the normal formaldehyde content of 0.06ppm found in the air of North American cities.

Imported OSB meets the formaldehyde emission requirements of the Republic of China National Standard (CNS-2215) Grade F1 and has obtained the commodity form recognition from the Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs.

Adventage of bestwood

-

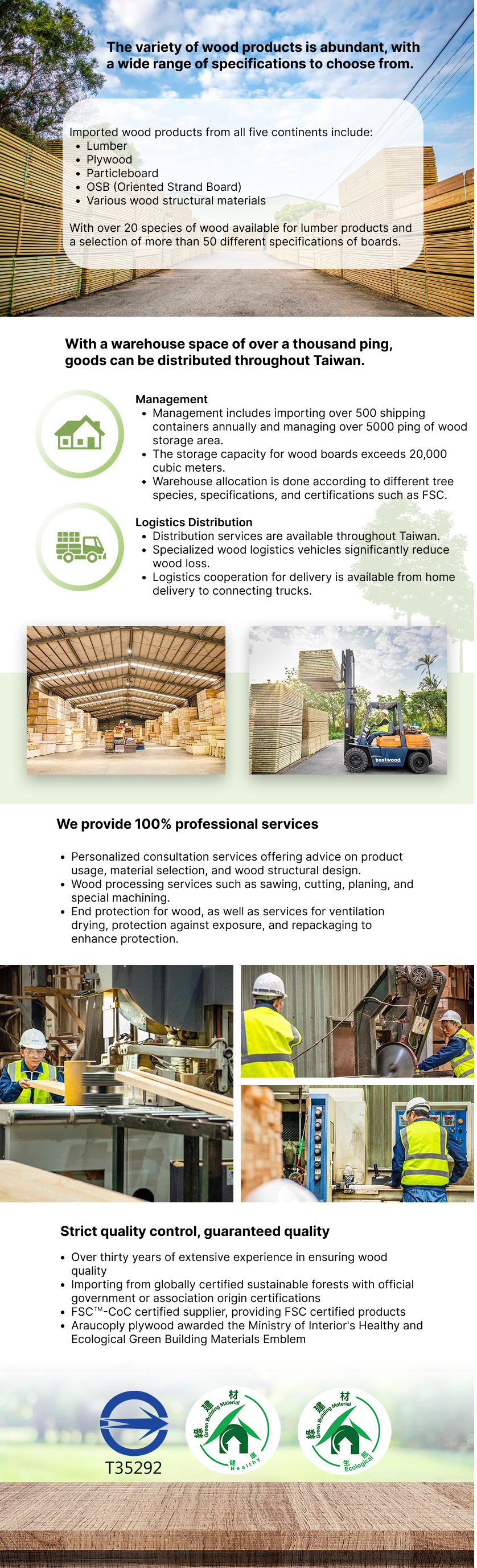

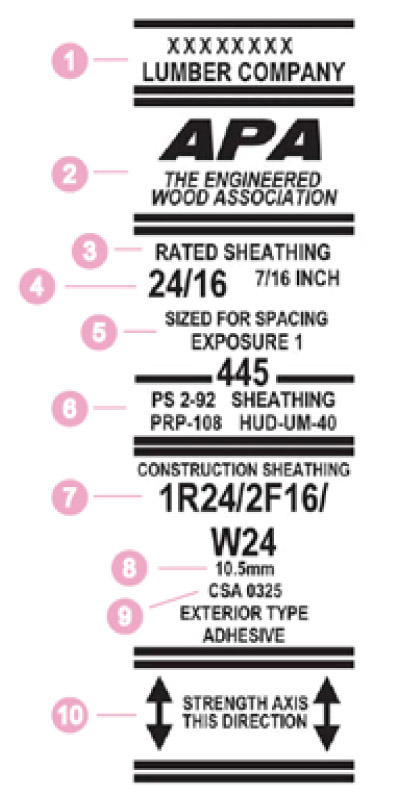

Depending on the region and specific requirements, OSB (Oriented Strand Board) is classified into various grades, broadly categorized into American and European standards:

• European Standard (Euro Specs): An example is OSB 3 grade, which has moisture-resistant properties. Even in damp environments, the boards retain structural integrity and are primarily used for manufacturing load-bearing furniture, packaging of mechanical and electrical products, and interior wall construction in wooden houses.

• American Standard (US Specs): OSB used in North America is often certified by the American Plywood Association (APA), making it suitable for direct application in decorative spaces or painting. It can even be used in house construction, particularly in the realm of "wood-framed wall panels," which are prevalent in North American building construction.

Common Uses of OSB in Domestic Settings:

• Wood Structures: Wood-framed wall panels (resistant to bending, warping, and deformation)

• Packaging Material: Pallets, outer packaging boxes for export goods

• Interior Decoration: Wall panels, ceilings, floors, wallboards

• Indoor Furniture: Wardrobes, sofas, bed frames, TV cabinets, modular furniture, office furniture

-

-

OSB Specifications

-

OSB Characteristic

OSB (Oriented Strand Board), unlike typical plywood and solid wood boards found in the market, is a special engineered wood panel product made by bonding layers of rectangular wood strands together from corner to corner.

The material used in OSB production isn't scrap wood from other processing activities but rather utilizes the entire log efficiently.

Manufacturing Process of OSB

During production, raw materials are sawn to specified dimensions, debarked, and processed into thin wood strands, typically averaging 4 inches long and 1 inch wide. After drying, these wood strands are mixed with adhesive resin and wax, then laid out in layers in alternating directions—vertically and horizontally—to enhance the density of the board and form a unique texture. Finally, the assembled layers undergo high-temperature continuous hot pressing to produce continuous panels of various thicknesses, which are then cut to the desired dimensions for construction and transportation.

Commonly used dimensions for OSB are 4 feet x 8 feet (1220mm x 2440mm).

Environmentally Friendly Wood Board

OSB emits very low levels of formaldehyde, typically as low as 0.012ppm. In fact, this emission level is lower than the normal formaldehyde content of 0.06ppm found in the air of North American cities.

Imported OSB meets the formaldehyde emission requirements of the Republic of China National Standard (CNS-2215) Grade F1 and has obtained the commodity form recognition from the Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs.

Adventage of bestwood

-

OSB ApplicationsDepending on the region and specific requirements, OSB (Oriented Strand Board) is classified into various grades, broadly categorized into American and European standards:

• European Standard (Euro Specs): An example is OSB 3 grade, which has moisture-resistant properties. Even in damp environments, the boards retain structural integrity and are primarily used for manufacturing load-bearing furniture, packaging of mechanical and electrical products, and interior wall construction in wooden houses.

• American Standard (US Specs): OSB used in North America is often certified by the American Plywood Association (APA), making it suitable for direct application in decorative spaces or painting. It can even be used in house construction, particularly in the realm of "wood-framed wall panels," which are prevalent in North American building construction.

Common Uses of OSB in Domestic Settings:

• Wood Structures: Wood-framed wall panels (resistant to bending, warping, and deformation)

• Packaging Material: Pallets, outer packaging boxes for export goods

• Interior Decoration: Wall panels, ceilings, floors, wallboards

• Indoor Furniture: Wardrobes, sofas, bed frames, TV cabinets, modular furniture, office furniture

-

OSB Standar

-

OSB Specifications

OSB Specifications